Prestressed Concrete Sleepers

Prestressed Concrete Sleepers Specification

- Technology

- Pre-tensioned Prestressing

- Color

- Gray

- Technics

- Centrifugal Moulding

- Weight

- 250 kg (approx.)

- Type

- Railway Sleeper

- Material

- High Strength Pre-stressed Concrete

- Dimensions

- 2500 mm x 300 mm x 210 mm (L x W x H)

- Hardness

- > 45 MPa

- Finish

- Smooth Surface Finish

- Tooling

- Formed with High-Precision Steel Moulds

- Surface

- Flat, Non-porous

- Water Absorption

- < 3% by mass

- Load Bearing Capacity

- At least 25 tonnes axle load

- Compressive Strength

- Minimum 50 MPa at 28 days

- Application

- Main Line and Branch Railway Track

- Fire Resistance

- High

- Sleepers per km

- 1660 1700

- Characterized By

- Corrosion Resistant

- Density

- 2400 2550 kg/m

- Conformance

- Indian Railways Standards - IRS:T-39

- Tensile Wire/Diameter

- 7-wire Strand, 9.5 mm diameter

- Feature

- Long Service Life, Maintenance Free

Prestressed Concrete Sleepers Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 50000 Boxes Per Month Per Month

- Delivery Time

- Months

- Packaging Details

- Wooden Boxes

- Main Domestic Market

- All India

About Prestressed Concrete Sleepers

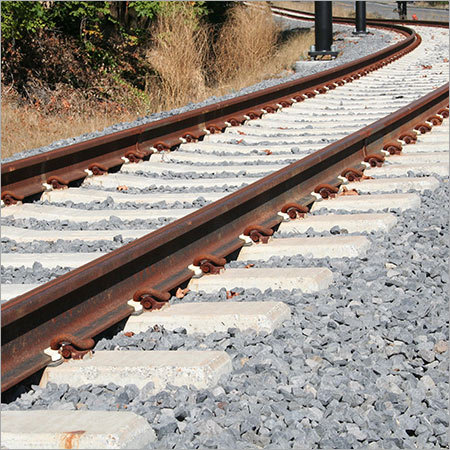

Prestressed Concrete Sleepers

We have been enlisted as a well known manufacturer and supplier of quality tested Prestressed Concrete Sleepers. Offered sleepers are constructed utilizing optimum quality concrete and other basic ingredients at well equipped production unit. These are extensively used for constructing railway tracks across the nation and highly demanded due to their dimensional accuracy. Additionally, the provided Prestressed Concrete Sleepers can be availed from us at marginal prices.

Key Points:

- Flawless design

- Easy installation

- Smooth finish

- Thermal resistance

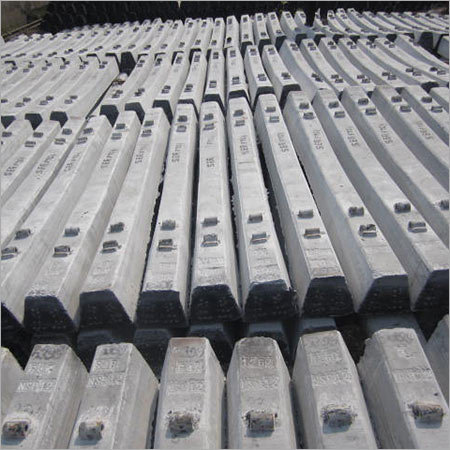

Superior Strength and Durability

Designed to meet stringent Indian Railways Standards, these prestressed concrete sleepers boast a compressive strength of over 50 MPa and a density range of 24002550 kg/m. Their robust composition guarantees high load-bearing capacity and prolonged service life, making them ideal for heavy main line and branch railway usage.

Advanced Manufacturing Process

Utilizing centrifugal moulding and pre-tensioned prestressing technology, every sleeper is formed with high-precision steel moulds, resulting in uniformity and excellent dimensional stability. The 7-wire strand reinforcement (9.5 mm diameter) enables superior tensile strength and corrosion resistance, ensuring reliability across diverse climates.

Maintenance-Free Performance

With a smooth, flat, non-porous surface and water absorption of less than 3%, these sleepers remain unaffected by environmental factors. Their fire-resistant and corrosion-resistant properties mean less frequent checks and negligible maintenance costs over the entire service life of the railway track.

FAQs of Prestressed Concrete Sleepers:

Q: How are prestressed concrete sleepers manufactured?

A: Prestressed concrete sleepers are produced using centrifugal moulding and pre-tensioned prestressing technology. High-strength concrete is poured into precision steel moulds and reinforced with 7-wire strands of 9.5 mm diameter, ensuring optimal durability and uniformity.Q: What standards do these sleepers adhere to for railway applications?

A: These sleepers strictly conform to Indian Railways Standards IRS:T-39, meeting all requirements for compressive strength, dimensional accuracy, load capacity, and longevity, making them suitable for main line and branch track installations.Q: When should railway operators choose prestressed concrete sleepers over alternative materials?

A: Prestressed concrete sleepers are recommended for locations requiring high load-bearing capacity, corrosion resistance, fire safety, and minimal maintenance, particularly in tracks exposed to harsh environmental conditions and heavy axle loads.Q: Where can these sleepers be installed and what is the recommended quantity per kilometer?

A: Applicable for main lines and branch tracks across India, these sleepers are installed at a rate of approximately 1660 to 1700 per kilometer, ensuring proper load distribution and track stability.Q: What are the primary benefits of using prestressed concrete sleepers for railway infrastructure?

A: Benefits include long service life, fire and corrosion resistance, high load capacity (up to 25 tonnes axle load), low water absorption, and virtually maintenance-free operation, contributing to reduced lifecycle costs for railway operators.Q: How does the sleepers surface finish impact its performance and longevity?

A: A smooth, flat, and non-porous surface finish, achieved through precision moulding, prevents water penetration and reduces wear, enhancing both durability and resistance to environmental factors.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Sleepers Category

Concrete Sleepers Blocks

Color : Grey

Technology : Prestressed concrete technology

Finish : Others, Smooth finish with chamfered edges

Tooling : Precision molds

Dimensions : Approx. 250 mm x 200 mm x 1600 mm

Weight : Approx. 4555 kg per block

Concrete Sleepers Mono Blocks

Color : Grey

Technology : Vibration Compacted

Finish : Others, Smooth

Tooling : Reinforced with highstrength steel wires

Dimensions : 1650 mm x 300 mm x 250 mm (approx.)

Weight : 150300 kg

Concrete Sleepers

Color : Grey

Technology : Vibration Compacting with Steam Curing

Finish : Others, Smooth Trowel Finish

Tooling : Precision Moulded

Dimensions : Length: 2750 mm, Width: 300 mm, Height: 210 mm

Weight : Approximately 250 kg per piece

Send Inquiry

Send Inquiry