Concrete Sleepers

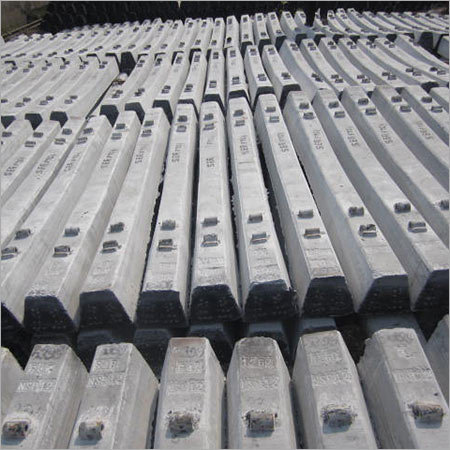

Concrete Sleepers Specification

- Color

- Grey

- Technics

- Pre-stressed Concrete Casting

- Technology

- Vibration Compacting with Steam Curing

- Weight

- Approximately 250 kg per piece

- Type

- Mono-block Concrete Sleeper

- Material

- High Strength Reinforced Concrete

- Dimensions

- Length: 2750 mm, Width: 300 mm, Height: 210 mm

- Hardness

- Up to 60 MPa (Compressive Strength)

- Finish

- Smooth Trowel Finish

- Tooling

- Precision Moulded

- Surface

- Smooth with Anti-slip Texture

- Load Bearing Capacity

- Suitable for Heavy & High-Speed Rail

- Maintenance

- Minimal, with Periodic Inspection

- Installation Method

- Mechanical Fastening with Clips

- Fire Resistance

- High - Non-combustible Material

- Environmental Resistance

- UV, Moisture, and Frost Resistant

- Expected Lifespan

- 35-50 Years

- Water Absorption

- Less than 3%

- Edge Profile

- Chamfered Edges for Safety

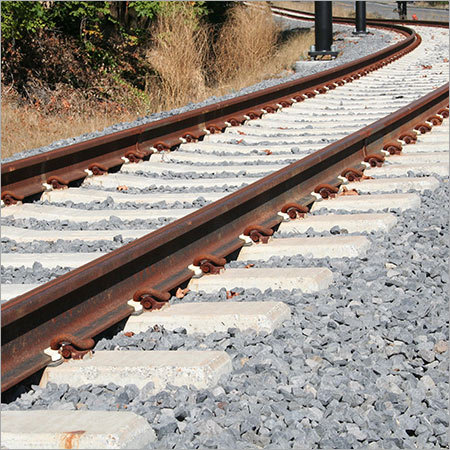

- Application

- Railway Track Foundation

Concrete Sleepers Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 50000 Boxes Per Month Per Month

- Delivery Time

- Months

- Packaging Details

- Wooden Boxes

- Main Domestic Market

- All India

About Concrete Sleepers

Concrete Sleepers

Being an illustrious firm in the global market, we are betrothed in manufacturing and supplying a wide assortment of pristine quality Concrete Sleepers. Offered sleepers are constructed utilizing optimum quality materials and innovative machines at well equipped production unit. These are used for constructing the railway tracks and known for their high strength. Moreover, the provided Concrete Sleepers can be availed from us at industry leading prices.

Key Points:

- Sturdy construction

- Abrasion resistance

- Durable finish

- High temperature resistance

Superior Load Bearing for High-Speed Rails

Designed specifically for heavy and high-speed railway applications, these concrete sleepers provide robust support, maintaining track stability under intense dynamic loads. Their high compressive strength up to 60 MPa and precise dimensions guarantee long-term performance and reduced track maintenance.

Engineered Durability in Extreme Conditions

Resistant to UV exposure, frost, and moisture, and with a fire-resistant, non-combustible composition, these sleepers thrive even in harsh climates. Manufactured with advanced vibration compacting and steam curing technology, they ensure longevity and minimal water absorption, extending sleeper life well beyond conventional alternatives.

Ease of Installation and Minimal Upkeep

Installation is streamlined through mechanical fastening with reliable clips, reducing setup time and complexity. Once installed, sleepers demand only periodic inspection, with negligible routine maintenance, ensuring a cost-effective life cycle and maximizing rail infrastructure uptime.

FAQs of Concrete Sleepers:

Q: How are concrete sleepers installed on railway tracks?

A: Concrete sleepers are installed using a mechanical fastening system with clips, securing them firmly to the rails. This ensures quick installation and improved stability for railway foundations.Q: What advantages do mono-block concrete sleepers offer over traditional timber sleepers?

A: Mono-block concrete sleepers deliver superior load-bearing capacity, extended lifespan (3550 years), higher fire resistance, and significantly greater resilience to environmental factors like UV exposure, moisture, and frost.Q: When is periodic maintenance required for these concrete sleepers?

A: Periodic inspection is recommended as part of regular rail track maintenance schedules. However, due to their robust design and material strength, these sleepers require minimal upkeep compared to other types.Q: Where are these concrete sleepers typically used?

A: These sleepers are ideal for heavy-duty and high-speed railway track foundations, especially in environments requiring high durability and stability, such as in Indias diverse climatic zones.Q: What is the manufacturing process for these sleepers?

A: Manufactured from high-strength pre-stressed reinforced concrete, sleepers are vibration compacted and steam-cured in precision moulds to achieve a dense, smooth finish and exceptional mechanical properties.Q: How does the chamfered edge profile benefit railway safety?

A: Chamfered edges reduce the risk of tripping and injury during installation and maintenance, improving on-site safety for workers.Q: What are the environmental and longevity benefits of using these sleepers?

A: With less than 3% water absorption, high UV, frost, and moisture resistance, and up to 50 years of service life, these sleepers reduce the need for replacement and lessen the environmental impact of maintenance operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Sleepers Category

Concrete Sleepers Blocks

Hardness : High strength, suitable for heavy loads

Color : Grey

Surface : Uniform and crackresistant

Technology : Prestressed concrete technology

Material : High quality reinforced concrete

Technics : Vibration casting

Concrete Sleepers Mono Blocks

Hardness : High compressive strength

Color : Grey

Surface : Even and durable

Technology : Vibration Compacted

Material : Prestressed Concrete

Technics : Moulding

Prestressed Concrete Sleepers

Hardness : > 45 MPa

Color : Gray

Surface : Flat, Nonporous

Technology : Pretensioned Prestressing

Material : High Strength Prestressed Concrete

Technics : Centrifugal Moulding

Send Inquiry

Send Inquiry