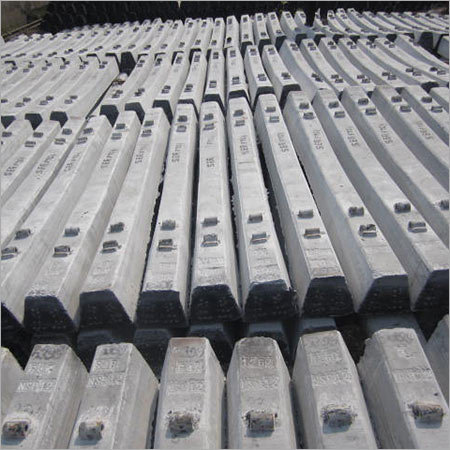

Concrete Sleepers Mono Blocks

Concrete Sleepers Mono Blocks Specification

- Technics

- Moulding

- Technology

- Vibration Compacted

- Color

- Grey

- Weight

- 150-300 kg

- Type

- Mono Block Concrete Sleeper

- Material

- Pre-stressed Concrete

- Dimensions

- 1650 mm x 300 mm x 250 mm (approx.)

- Hardness

- High compressive strength

- Finish

- Smooth

- Tooling

- Reinforced with high-strength steel wires

- Surface

- Even and durable

Concrete Sleepers Mono Blocks Trade Information

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 50000 Boxes Per Month Per Month

- Delivery Time

- Months

- Packaging Details

- Wooden Boxes

- Main Domestic Market

- All India

About Concrete Sleepers Mono Blocks

Concrete Sleepers Mono Blocks

Being a versatile entity in this domain, we are instrumental in manufacturing and supplying a wide assortment of Concrete Sleepers Mono Blocks. Offered blocks are constructed utilizing optimum quality concrete and other basic ingredients at well equipped production unit. These blocks are used for making railway tracks and appreciated due to their dimensional accuracy. Additionally, the provided Concrete Sleepers Mono Blocks can be availed from us at marginal prices.

Key Points:

- Flawless design

- Easy installation

- Smooth finish

- Thermal resistance

Robust Load-Bearing Performance

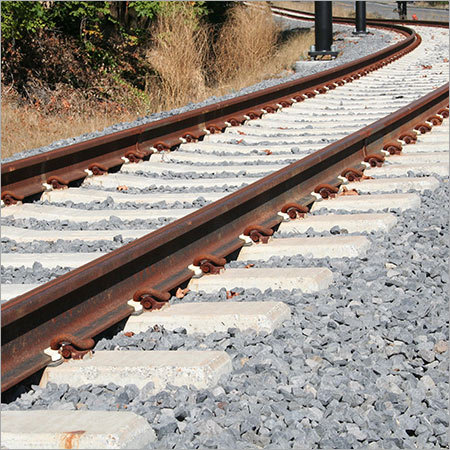

Engineered for railway track support, Mono Block Concrete Sleepers are capable of supporting axle loads up to 25 tons. The use of high-strength steel wire reinforcement and pre-stressed concrete ensures high compressive strength, making them suitable for intensive rail traffic and heavy-duty applications.

Durability in Challenging Environments

Designed to withstand harsh weather, chemical exposure, and pest attack, these sleepers feature excellent crack resistance and low water absorption. Their durable, even surface resists degradation, ensuring consistent performance throughout their 40-50 year service life.

Flexible Installation Methods

Mono Block Concrete Sleepers can be laid both mechanically and manually, allowing for rapid deployment and adaptation to different project requirements. Their uniform dimensions and weight facilitate straightforward placement and alignment during railway construction or maintenance.

FAQs of Concrete Sleepers Mono Blocks:

Q: How are Mono Block Concrete Sleepers installed on railway tracks?

A: These sleepers are designed for flexible installation and can be laid either mechanically using specialized equipment or manually, depending on the site requirements and available resources.Q: What benefits do Mono Block Concrete Sleepers offer for railway infrastructure?

A: They provide high load-bearing capacity, exceptional durability, and resistance to cracks, chemicals, and weather. Their long lifespan reduces maintenance needs, resulting in cost savings and safer rail operations.Q: When is it ideal to use Mono Block Concrete Sleepers in rail projects?

A: Mono Block Concrete Sleepers are suitable for both new railway track installations and track renewals, especially where high axle loads and long-term durability are required.Q: Where can these sleepers be utilized in railway construction?

A: They are applicable in a wide range of railway projects across India, including mainline, siding, and industrial track installations, given their robust construction and high performance.Q: What process is used in manufacturing these concrete sleepers?

A: The sleepers are produced using a moulding process combined with vibration compaction technology, employing pre-stressed concrete reinforced with high-strength steel wires for superior strength and longevity.Q: How does the low water absorption feature benefit these sleepers?

A: With less than 2% water absorption, the sleepers exhibit increased durability by minimizing the risk of freeze-thaw damage and preventing internal deterioration, especially in humid or wet environments.Q: What is the estimated service life of Mono Block Concrete Sleepers?

A: These sleepers are engineered to last approximately 40 to 50 years, offering long-term performance with minimal maintenance requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Sleepers Category

Concrete Sleepers Blocks

Weight : Approx. 4555 kg per block

Technics : Vibration casting

Dimensions : Approx. 250 mm x 200 mm x 1600 mm

Technology : Prestressed concrete technology

Type : Railway sleeper block

Surface : Uniform and crackresistant

Prestressed Concrete Sleepers

Weight : 250 kg (approx.)

Technics : Centrifugal Moulding

Dimensions : 2500 mm x 300 mm x 210 mm (L x W x H)

Technology : Pretensioned Prestressing

Type : Railway Sleeper

Surface : Flat, Nonporous

Concrete Sleepers

Weight : Approximately 250 kg per piece

Technics : Prestressed Concrete Casting

Dimensions : Length: 2750 mm, Width: 300 mm, Height: 210 mm

Technology : Vibration Compacting with Steam Curing

Type : Monoblock Concrete Sleeper

Surface : Smooth with Antislip Texture

Send Inquiry

Send Inquiry