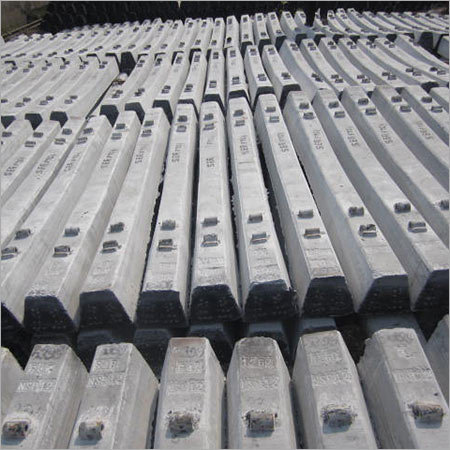

Concrete Sleepers Blocks

Concrete Sleepers Blocks Specification

- Technics

- Vibration casting

- Technology

- Pre-stressed concrete technology

- Weight

- Approx. 45-55 kg per block

- Color

- Grey

- Type

- Railway sleeper block

- Material

- High quality reinforced concrete

- Dimensions

- Approx. 250 mm x 200 mm x 1600 mm

- Hardness

- High strength, suitable for heavy loads

- Finish

- Smooth finish with chamfered edges

- Tooling

- Precision molds

- Surface

- Uniform and crack-resistant

Concrete Sleepers Blocks Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash in Advance (CID), Cheque

- Supply Ability

- 50000 Pieces Boxes Per Month Per Month

- Delivery Time

- Months

- Packaging Details

- Wooden Boxes

- Main Domestic Market

- All India

About Concrete Sleepers Blocks

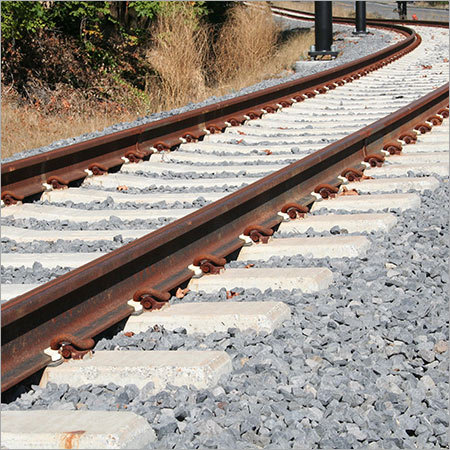

Concrete Sleepers Blocks

Backed by team of dedicated professionals, we are instrumental in manufacturing and supplying a wide assortment of Concrete Sleepers Blocks. Offered blocks are constructed utilizing optimum quality concrete and other basic ingredients at well equipped production unit. These are extensively used for constructing railway tracks connecting all over the world and highly demanded due to their dimensional accuracy. Additionally, the provided Concrete Sleepers Blocks can be availed from us at marginal prices.

Key Points:

- Robust design

- Longer life

- Resist sun exposure

- Thermal resistance

Engineered for Durability and Reliability

These concrete sleeper blocks are crafted using advanced pre-stressed technology with M50 grade concrete, delivering high strength and exceptional load-bearing performance. Resistant to weather, chemicals, oil, and fire, they ensure reliable service even under demanding industrial or rail environments, lasting over 50 years with minimal maintenance.

Compliant and Sustainable Solutions

Manufactured in accordance with Indian Railway Standards (IRS) and IS 456:2000, our concrete sleeper blocks are made from sustainable materials. The eco-friendly production process, combined with precision vibration casting, ensures uniformity, dimensional accuracy, and a crack-resistant surface, making them a responsible, long-term choice.

FAQs of Concrete Sleepers Blocks:

Q: How are these concrete sleeper blocks installed?

A: These blocks can be installed either mechanically or manually, depending on the project scale. Their beveled edges and uniform dimensions facilitate straightforward alignment and placement, streamlining the installation process for railway, metro, or industrial projects.Q: What makes these railway sleeper blocks suitable for heavy loads?

A: Constructed from M50 equivalent pre-stressed reinforced concrete, these sleeper blocks can support loads up to 60 tons. Precision vibration casting ensures high density and compressive strength, making them ideal for areas with significant dynamic or static loads such as railway tracks and industrial zones.Q: When and where should these sleeper blocks be used?

A: These blocks are best suited for railway tracks, metro lines, and industrial sidings where high load capacity and long-term durability are required. Their excellent fire, chemical, and weather resistance makes them suitable for challenging outdoor and industrial environments.Q: What is the process used to manufacture these concrete sleepers?

A: The sleeper blocks are manufactured using vibration casting technology with precision molds, ensuring uniform compaction, consistent dimensions, and smooth, crack-resistant surfaces. The pre-stressed concrete process further enhances tensile strength and overall durability.Q: What maintenance do these sleeper blocks require?

A: These concrete sleepers are designed for low maintenance. Their resistance to chemicals, weathering, and oil, alongside a smooth, uniform finish, minimizes the need for repairs or upkeep over their 50+ year service life.Q: What are the environmental benefits of using these blocks?

A: Produced from sustainable materials and through eco-friendly processes, these sleeper blocks reduce environmental impact. Their long lifespan and minimal maintenance requirements also result in lower resource consumption over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Concrete Sleepers Category

Concrete Sleepers Mono Blocks

Technology : Vibration Compacted

Type : Mono Block Concrete Sleeper

Weight : 150300 kg

Material : Prestressed Concrete

Technics : Moulding

Finish : Others, Smooth

Concrete Sleepers

Technology : Vibration Compacting with Steam Curing

Type : Monoblock Concrete Sleeper

Weight : Approximately 250 kg per piece

Material : High Strength Reinforced Concrete

Technics : Prestressed Concrete Casting

Finish : Others, Smooth Trowel Finish

Prestressed Concrete Sleepers

Technology : Pretensioned Prestressing

Type : Railway Sleeper

Weight : 250 kg (approx.)

Material : High Strength Prestressed Concrete

Technics : Centrifugal Moulding

Finish : Others, Smooth Surface Finish

Send Inquiry

Send Inquiry